LSR Injection Molding Service

- Time:2025-06-27

- Source:创始人

What Is LSR Injection Molding?

LSR injection molding is a manufacturing process where rubber is injected into a custom mold under high pressure, then heated to cure and harden into the desired shape. This method produces precise, durable, and complex silicone parts with consistent quality, making it ideal for both low-volume and high-volume production. It’s commonly used to create parts like seals, gaskets, and other custom rubber components across various industries, including automotive, medical, and consumer goods. LSR injection molding offers exceptional design flexibility, the ability to use a wide range of rubber materials, and ensures high production efficiency, making it a preferred choice for manufacturers.

LSR is ideal for many demanding applications due to its unique combination of properties:

l Highly flexible and elastic, staying soft and rubbery even in extreme temperatures and it bounces back well after stretching or compression;

l Stands up to water, acids, alkalis and many solvents, remaining stable even when exposed to UV light, ozone or other harsh conditions;

l Maintains its strength and shape over time across a wide thermal range, typically from -50℃ to +250℃;

l Non-toxic, hypoallergenic, and safe for direct skin contact and medical use;

l Incredibly durable;

l Resists fatigue and weathering with ease.

Injection Rubber Molding Material

We offer a wide selection of rubber materials for injection molding, tailored to meet the specific needs of various industries. Our range includes standard rubber, medical-grade rubber, and optical-grade rubber, with hardness options ranging from Shore A 5 to 95. Our rubber materials include:

Comparing between LSR, tranditional silicone and TPE:

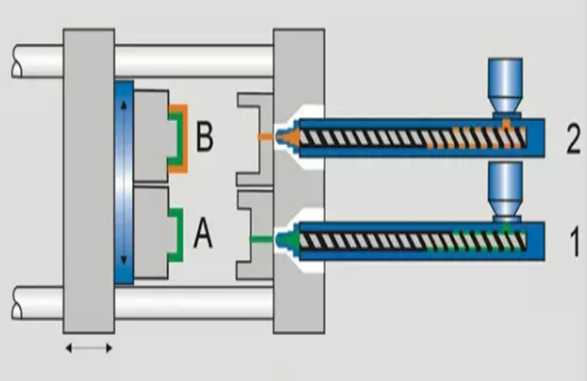

How Does LSR Injection Molding Work?

LSR Injection Molding Service process is a high efficient method for producing a wide range of rubber parts. Our advanced machinery and experienced team ensure precision control over each step of the process, resulting in high-quality, consistent and cost-effective production of custom rubber parts. The injection molding process involves several key steps:

Mold Preparation

The first step is designing and preparing the mold. This includes selecting the right mold material, ensuring its dimensions match the part specifications, and preheating the mold to the required temperature. Molds are typically created based on CAD designs of the product.

Material Preparation

The selected rubber material, such as EPDM, Silicone or Nitrile, is prepared and loaded into the injection molding machine. The rubber is heated to a specific temperature to make it flowable and ready for injection into the mold. The rubber's viscosity is carefully controlled to ensure optimal flow during molding.

Injection Molding

The heated, viscous rubber is injected under high pressure into the custom-designed injection mold cavity. This step ensures the mold is completely filled, capturing all intricate details and achieving precise part dimensions. The injection molding process allows for high-volume production of custom rubber parts, ensuring consistent quality and excellent elasticity, durability, and performance

Curing or Vulcanization

Once injected, the rubber undergoes vulcanization or curing. During this stage, the rubber is subjected to heat, which causes cross-linking of polymer chains. This process gives the rubber its strength, elasticity, and durability, making it suitable for long-lasting applications like automotive seals or medical components.

Cooling and Ejection(Demolding)

After curing, the mold is cooled, solidifying the rubber part. Once cooled, the mold is opened, and the finished molded rubber parts are ejected. Excess material, such as flash, is trimmed off to ensure a smooth finish.

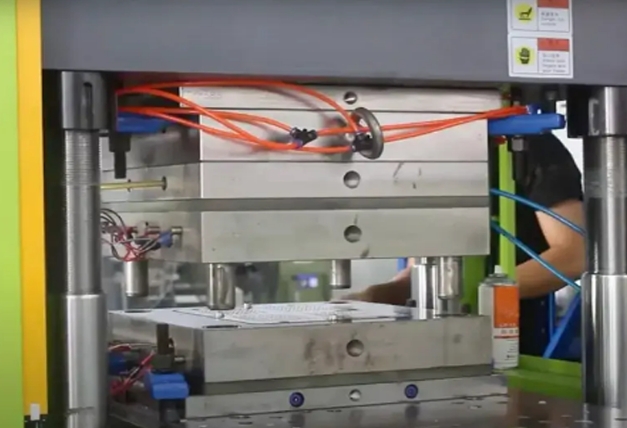

Our Custom Mold Manufacturing Capability

Our custom contract manufacturing capabilities offer custom solutions to meet the specific needs of your business. We well equipped with top of the line manufacturing machines to achieve high quality precision molds, which also derived from proper mold design, strong project management, skilled employees & strict quality control.

Advantages of LSR Injection Molding

· High accuracy and consistency

· Improve production efficiency

· High material utilization

· Adapt to complex design

· Reduced labor costs

· Reduced post-processing requirements:

LSR Molding Application

LSR injection molding service is used in a wide range of industries, especially in scenarios that require high-volume production of durable and precision components, including:

· Medical: LSR is highly valued in the medical field due to its biocompatibility, chemical resistance and flexibility. It complies with stringent FDA and ISO standards. Key applications include seals, gaskets that ensure fluid or airtight barriers, especially in surgical tools and diagnostic equipment, valves for respiratory and infusion devices, and wearable health devices like bands and sensor housings.

· Baby&Pet care: Based on 100% food grade material and medical grade silicone, LSR was used widely in baby-care, such as nipples, feeding-bottle, toys.

· Consumer products: LSR is popular because of its versatility, design flexibility and safe skin contact properties. Key applications include houseware for Kitchen & bathroom, like cooking tools, lunch boxes, gloves, phone accessories and wearable technology such as smart watch bands and fitness tracker casings.

· Automotive: LSR’s thermal stability, weather resistance and durability make it ideal for safety-critical parts and components exposed to prolonged heat. Some applications include o-rings, sealing for engines and transmissions, connectors for electrical systems, and grommets to protect wiring and cables.

· Industrial Applications: LSR is used in industrial environments where high performance, durability and precision are required in challenging conditions. Some key applications are sealing system, electronics enclosures, electrical insulators and fluid control components.

Conclusion

LSR rubber molding offers a powerful combination of flexibility, durability and biocompatibility, making it ideal for a wide range of applications.

At XHT, we help you make smart, informed decision about the best manufacturing method for your products. It is important to consider your material requirements, design complexity, regulatory compliance needs and production volume and speed. Our experts are here to guide you every step of the way.