2-Shots Molding Service

- Time:2025-06-27

- Source:创始人

What is 2-Shot Injection Molding?

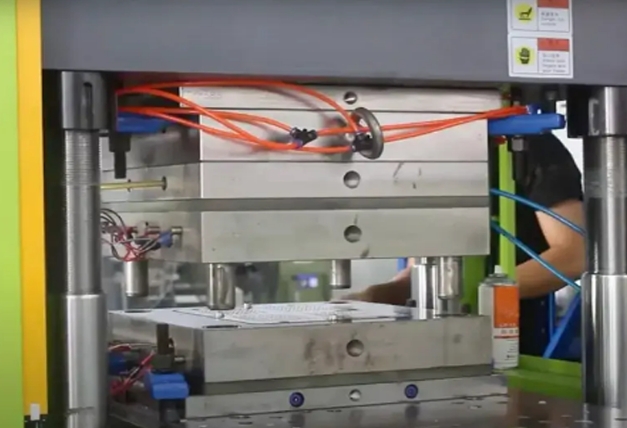

2-shot plastic injection molding is a process of injecting two different plastic materials in two separate or simultaneous shots into an injection plastic mold to manufacture a single solid part. The colors, textures, rigidity, or even functions of these materials may not be similar to each other, creating more versatility and complexity in product design.

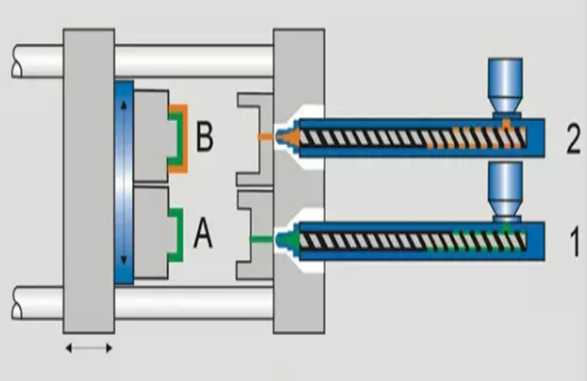

This process requires a specialized two-shot injection molding machine equipped with two separate sets of screws and barrels. This technology is capable to produce components with both aesthetic appeal and functional strength, finding widespread applications in the automotive, consumer electronics, and medical equipment industries.

The Process of 2 Shot Injection Molding

The process of two-shot molding is outlined as follows, highlighting the intricate steps involved in creating a composite component within a single molding cycle:

Mold Design and Manufacture: Two-shot molding necessitates the use of a specialized two-shot injection molding machine and precisely designed molds. The design of the mold must take into account the flow, cooling, and solidification characteristics of both materials to ensure they combine correctly within the mold. The steps are as follows:

1.First Injection: The process begins with the injection of the first material into one of the injection units of the molding machine, forming part of the product. Once this step is completed, the partially formed component remains fixed within the mold or is moved to another position through rotation or shifting of the mold.

2.Mold Rotation or Shifting: For some two-shot molding processes, the semi-finished product from the first injection needs to be transferred within the mold to a second injection position. This can be achieved by rotating or shifting the mold, depending on the design of the two-shot molding machine used.

3.Second Injection: After the first part has solidified and been moved to the second position, the second material is injected into the mold through another injection unit, bonding with the first part to form the final product. This step requires precise control to ensure good adhesion between the two materials.

4.Cooling and Solidification: Following the injection of the second material, the entire component cools and solidifies within the mold. This stage is critical for the quality of the product, necessitating precise control over cooling speed and time.

5.Mold Opening and Ejection: After cooling and solidification, the mold is opened, and the finished two-color product is ejected.

This detailed process showcases the technical complexity and precision required in two-shot molding, allowing for the production of high-quality, multifunctional components used across various industries.

Advantages and Disadvantages of Two-Shot Molding

Two-shot molding has the distinct advantage of producing complex, high-quality products with diverse appearances in a single molding cycle. It can reduce post-processing steps, enhance production efficiency, and lower costs. However, this technology demands high requirements for mold design and manufacturing, leading to relatively high initial investments.

Advantages:

Reduced Production Steps and Costs: This method consolidates the injection of multiple materials into one cycle, eliminating subsequent processes and lowering both production costs and time.

Enhanced Product Quality: Two-shot molding can produce more durable, structurally stable products. The integration of two materials can improve overall performance, such as impact resistance and sealing properties.

Design Flexibility: It allows designers to combine different colors or types of plastics in one component, offering unique visual and tactile qualities.

Disadvantages:

Higher Mold Costs: The complex requirements for two-shot molds result in higher costs. Designing and manufacturing these molds demand extensive experience and precision, significantly increasing initial investments compared to traditional molding techniques.

Increased Production Hourly Rates: Specialized two-shot molding machines are more expensive than standard injection molding machines. Additionally, operating these machines requires specialized skills, contributing to higher hourly rates.

Environmental Concerns: Utilizing two distinct materials complicates recycling efforts, as effectively separating these materials can be challenging. The complexity of recycling and the inability to reuse production rejects pose significant challenges for two-shot molding.

Mold Requirements for 2-Shot Molding

Two-shot molding, a sophisticated injection molding technique that simultaneously uses two different materials or colors in the same molding process, demands highly precise molds. Ensuring the success of this process involves strict control over several aspects.

Alignment Precision: The precision of mold alignment is crucial. Two-shot molding employs molds that include two sets of lower molds (moveable) and two sets of upper molds (stationary), which need to rotate or shift during the molding process to align interchangeably. It is essential to ensure that both sets of molds are completely consistent in terms of outer dimensions, internal cavities, and height.

Typically, a CMM (Coordinate Measuring Machine, a three-dimensional measuring equipment) is used in production to check the precision of the molds, preventing injection molding defects such as flash due to misalignment.

Rigorous Mold Design and Review: The mold design and review process must be highly meticulous. Given the high cost of two-shot molds, any flaws in the design could lead to modifications in both sets of molds, thereby incurring additional costs. Therefore, the design stage of the molds must carefully consider various elements, including the design of gates and runners, the arrangement of sliders, and the layout of the cooling system. These aspects require thorough verification and validation to ensure no oversight.

Automatic Degating: Considering the emphasis on production efficiency in two-shot molding, mold designs should aim for automatic degating whenever possible. This means that at the end of the injection molding process, excess material from the injection ports can be automatically removed from the product without manual intervention. This reduces labor costs and enhances production efficiency.

Considerations for Effective 2 Shot Molding

In two-shot molding, the bonding between the substrate and the overmolding layer is achieved through chemical and physical processes, involving material selection, mold design, and processing conditions. This bonding process ensures that two different materials tightly integrate in the final product, forming a structurally intact and functionally robust composite. Here are several key factors in this bonding process:

Material Selection and Compatibility: Choosing compatible materials is crucial for a successful bond. The substrate and overmolding materials must be compatible in their molten states without adverse chemical reactions. Material suppliers often provide guidance on which material pairings achieve the best adhesion.

Surface Treatment: In some cases, the substrate’s surface may undergo special treatments such as sandblasting, chemical etching, or surface activation to increase its roughness and chemical reactivity, thereby enhancing the bond strength with the overmolding layer.

Mold Design: Mold design is also critical in ensuring a good combination of the two materials. The mold must precisely control the flow path of each material, ensuring that the second material forms a stable and uniform coverage over the first material’s surface.

Injection Molding Parameters:The parameters during the injection molding process, such as temperature, pressure, and cooling time, need careful adjustment to suit the characteristics of both materials. Proper temperature and pressure can promote good material bonding, while the right cooling time ensures that the materials solidify without internal stress, affecting the bond strength.

Aesthetics and Function: The second shot can be employed to enhance both the part’s visual aspect and functionality. Overmolding of a soft-touch material to a rigid substrate, for example, can be used to create better grip or comfort. Colors contrasting with each other or transparent elements can help with branding, usability, or product recognition.

Molecular Diffusion: At the interface of the two materials in their molten state, molecular diffusion occurs, meaning molecules from one material penetrate into the other. This helps form stronger chemical bonds and physical entanglements, enhancing the adhesion between the two materials

Commonly Used Materials

· Substrate Materials: ABS, PC, PC/ABS, PP, PMMA, PA6, PA66, etc.

· Overmolding Materials: TPE, TPU, Silicone, and hard plastic materials used as substrates.

Consulting with material suppliers is advisable to confirm the compatibility of the two materials.

Through the methods and mechanisms described above, two-shot molding can achieve a tight bond between the substrate and the overmolding layer, producing composite material products that are both aesthetically pleasing and high-performing. This technology is widely applied in various fields such as electronic devices, automotive parts, and medical instruments, offering more possibilities for product design and functionality.

Comparison Between 2-Shot Molding and Overmolding

When discussing two-shot molding technology, it’s common to compare it with overmolding. Though these two techniques seem similar in many aspects, involving multiple (two or more) injection molding processes, there are key differences between them.

In conclusion, while both two-shot molding and overmolding serve to create composite materials through multiple injection processes, they each offer unique benefits suited to different manufacturing needs. Choosing between the two depends on specific project requirements, costs, and desired outcomes.

2-Shot Injection Molding Challenges & Solutions

Let’s discuss these challenges and their solutions in depth.

Challenges:

· Tooling cost and complexity

· Material compatibility issues

· Limited machinery availability

· Poor bonding potential or warping

Solutions:

· Conducting material compatibility tests

· Advanced mold flow simulation software is used.

· Partnering with specialized 2-shot molding providers

· Investing in high-precision tooling

Conclusion

In summary, two-shot molding is an advanced injection molding technique that efficiently combines two different materials or colors in a single cycle, offering significant advantages in terms of design flexibility, product quality, and production efficiency. Despite its higher initial investment in mold design and machinery, the technology presents a compelling case for applications requiring complex, multi-material components with high precision and strength.