Over-Molding Service

- Time:2025-06-27

- Source:创始人

What is Over-molding Process?

Over-molding is a multi-step injection molding process where two or more materials are molded together to create a single, integrated component. This process typically begins with the creation of a base component, known as the substrate, which is usually made from a rigid material such as plastic or metal, that can be partially or entirely enveloped by additional materials (known as over-molded materials), to create a single or multi-material component. This technique not only simplifies the production process by reducing the need for secondary assembly but also enhances the performance characteristics of the final product, such as functionality, aesthetics, durability and user experience, making it suitable for a wide range of applications, from consumer goods to industrial components.

Material Combinations and Compatibility

Here are the most common combinations we use:

1. Hard Substrate Materials:

◦ ABS (Acrylonitrile Butadiene Styrene)

◦ PC (Polycarbonate)

◦ Nylon

◦ PP (Polypropylene)

2. Over-molding Materials:

◦ TPE (Thermoplastic Elastomer)

◦ TPU (Thermoplastic Polyurethane)

◦ Silicone

◦ Soft PVC

Steps in the Over-molding Process and Considerations

The over-moulding process involves several critical steps that ensure the successful integration of different materials into a single part. Each step is essential for achieving the desired performance and aesthetic qualities of the final product.

Step 1: Material Selection

The first step in the over-molding process is selecting the appropriate materials for both the substrate and the

over-mold. Key criteria for material selection include:

• Compatibility: The substrate and over-mold materials must bond effectively during the molding process. This often involves choosing materials with similar thermal properties and chemical compatibility.

• Mechanical Properties: Consideration of tensile strength, flexibility, and durability is crucial to ensure that the final product meets performance requirements.

• Aesthetic Qualities: The color, texture, and finish of the over-mold can significantly affect the product’s appearance, making it essential to choose materials that align with design goals.

• Cost: Budget constraints may influence material choices, so balancing performance with cost-effectiveness is vital.

Step 2: Mold Design and Setup

Once materials are selected, the next step is mold design and setup. This phase involves several considerations:

• Mold Construction: The mold must be designed to accommodate both the substrate and the over-mold materials. Precision in mold design is critical to ensure proper fit and function.

• Runner Design: The runner system must be optimized for efficient material flow during injection. This includes minimizing waste while ensuring uniform distribution of materials.

• Gate Design: Gate placement affects how materials enter the mold cavity. Proper gate design can help prevent issues such as short shots or uneven fill, which are crucial for achieving high-quality over-molds.

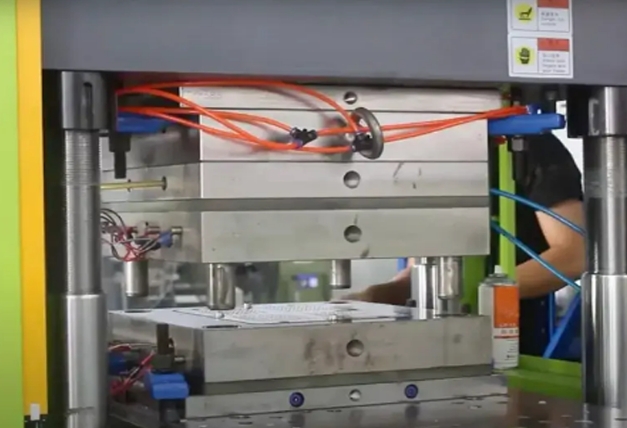

Step 3: Injection and Cooling

In this step, the actual injection of materials takes place:

• Injection Process: The substrate material is injected into the mold first, followed by the over-mold material. Careful control of injection speed and pressure is necessary to ensure proper filling and bonding between layers.

• Cooling Management: Cooling rates must be monitored closely to prevent warping or defects in the final part. Effective cooling strategies help maintain dimensional stability and enhance surface quality.

Step 4: Ejection and Inspection

After cooling, parts need to be ejected from the mold:

• Part Ejection Methods: Various techniques can be used to eject parts from molds, including mechanical ejectors or pneumatic systems. The method chosen should minimize stress on the part to avoid damage.

• Quality Control Checks: Inspecting parts for defects such as incomplete fills, surface imperfections, or bonding issues is essential.

Step 5: Post-Processing

The final step in the over-molding process involves additional finishing processes: these may include trimming excess material, surface polishing, or applying coatings to enhance aesthetics and functionality. Post-processing can significantly improve product appeal and performance.

Types of Over-molding and Over-molding Processes

Manufacturers in the plastics industry rely on a range of advanced over-molding techniques to create high-performance products. Over-molding—sometimes called multi-material injection molding or multi-shot molding—is the process of bonding two or more materials to produce a single finished component. The choice of over-molding technology depends on the substrate materials, design objectives, and the specific manufacturing requirements. Understanding the primary over-molding processes and their capabilities is essential when selecting a plastic injection molding partner or evaluating the right technique for your application.

Four Types of Over-molding

Not every material combination or product design is suitable for over-molding. However, four main types of over-molding techniques are widely utilized across various industries, including automotive, medical device manufacturing, consumer electronics, and industrial machinery construction:

• Plastic Over Plastic: In this common method, plastic resin is used for both the substrate (base layer) and the material molded on top. Thermoplastics like PC, ABS, and PP are often selected for their similar melting points, enabling secure molecular bonding in the injection mold. This technique is ideal for ergonomically enhanced grips, protective casings, and components with multi-colored or dual-hardness surfaces.

• Plastic Over Metal: In plastic-over-metal over-molding, a metal substrate—such as stainless steel, aluminum, or brass—is placed inside the injection mold. Once positioned, molten plastic is injected, encapsulating the metal insert and forming a strong structural bond. The result is a composite part with the durability of metal and the design flexibility of engineered polymers. This method is widely used for automotive gears, electrical connectors, and medical instruments requiring both conductivity and protective barriers.

• Elastomer Over Plastic: Over-molding thermoplastic elastomers (TPE), thermoplastic vulcanizates (TPV), or rubber-like polyurethane onto a rigid plastic substrate creates soft-touch surfaces, ergonomic handles, seals, and vibration-damping gaskets. This combination provides excellent grip, enhanced comfort, and improved sealing properties, which are vital for medical devices, handheld tools, and appliance components.

• Elastomer Over Metal: In this approach, a metal core is used as the substrate. Over-molding rubber-like elastomers over CNC-machined, die-cast, or forged metal inserts enables manufacturers to engineer components with enhanced shock absorption, improved ergonomics, and reliable environmental sealing. Typical applications include industrial tool handles, vibration dampeners, and custom grommets or bushings.

Choosing the correct combination of substrate and over-mold material is critical for optimal adhesion, part durability, and end-use performance. Consulting with an experienced injection molding supplier early in your product development cycle can help determine material compatibility, improve cost efficiency, and ensure your parts meet rigorous industry standards.

Types of Over-molding Processes

Various manufacturing processes enable over-molding, each suited to different part designs, production volumes, and material requirements. Selecting the ideal over-molding process can achieve higher mechanical strength, better product aesthetics, reduced assembly costs and faster time to market. Here is an overview of the leading over-molding processes used in modern manufacturing:

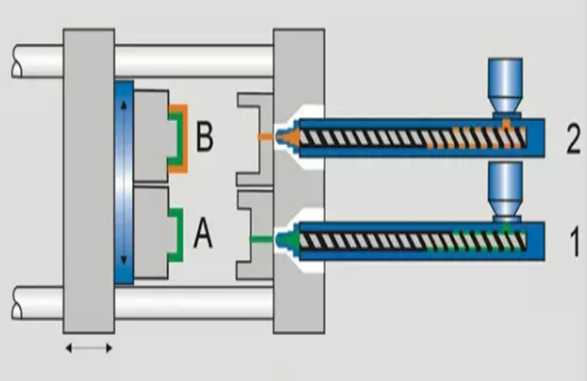

• Injection Over-molding

Dual-injection molding (also known as co-injection) is a state-of-the-art over-molding technique widely used in the plastics industry for producing complex, multi-material components in automated cycle. Unlike manual insert molding, dual-injection utilizes precision multi-barrel injection molding machines to inject both the substrate and the over-mold material into the same cavity, often simultaneously or sequentially. Because both materials are in a molten state, this process enables superior molecular bonding, intricate design features, and enhanced visual appeal. Injection over-molding is chosen for high-volume production runs of products that demand strong bonds and aesthetic differentiation, such as electronic housings, automotive dashboard panels, and medical device enclosures.

• Insert Molding

Insert molding is the most cost-effective and versatile technique for over-molding applications involving pre-formed components. This method is widely used to embed metal inserts, threaded fasteners or bushings into plastic parts, resulting in enhanced strength, improved electrical performance, and seamless integration of multi-component assemblies. The process involves placing the insert (rigid or flexible) into the mold cavity, followed by the injection of resin to encapsulate the insert. Strong adhesion is achieved as the molten plastic or elastomer bonds chemically and mechanically with the inserted component. Often required for electronics enclosures, medical housing parts, custom knobs, and high-wear tools, insert molding streamlines assembly, boosts part integrity, and minimizes labor costs.

When evaluating which over-molding process is best suited for your application, consider factors such as target production volume, material compatibility, tooling investment, product complexity, and desired physical or functional properties. Successful over-molding projects start with early consultation, precise material selection, and a partnership with an experienced injection molding or casting provider. In doing so, you can ensure your products meet exacting performance standards, regulatory requirements, and user expectations.

Applications of over-molding

• Cookware & Household Goods

Food safety is crucial when using plastic for items such as cookware, food containers and kitchen utensils. Over-molding is employed in cookware for various components, including spatula handles, pot covers, stove trims, knives, and cutting boards. These products utilize high-grade polymers that ensure food flavor and freshness are not compromised, enhancing consumer safety. Also it's no surprise that many household items, such as toothbrushes, kitchen utensils, portable electric fans, mirrors, pens, multi-port chargers, shampoo bottles, and reusable food containers, are produced using over-molding. This process not only makes products easier to clean and use, but also reduces wear and tear, extending their lifespan and improving overall quality for users.

• Hardware Tools

Various hardware tools serve as excellent examples of over-molding in action. These tools include blades, pocket knives, pliers, wrenches, hammers, tape measures and other similar items.

The primary components of these tools are usually made from steel, which is utilized for cutting, bending, drawing, punching, and various other fabrication processes. However, for the tools to be used safely and ergonomically by the end-user, over-molding plays a crucial role in enhancing their handleability and comfort.

Using common tools can be challenging without over-molded handles, whether you're working on automotive repairs or home improvement projects. The substrate for the over-molding process can be made from various polymers. In a two-step injection molding procedure, a rubberized plastic is then added to this substrate to create the handle, improving the user's grip and overall comfort.

• Medical Equipment

Precision and product safety are crucial in the medical sector. For instance, surgical tools used by doctors, surgeons and nurses must be made from reliable, safe plastic materials. Furthermore, these tools should be designed for easy cleaning and sterilization to prevent infections.

Over-molding is widely employed in the medical industry to enhance various products. It is used to manufacture components such as equipment housings and surgical instruments, creating finished parts that improve usability. Examples include syringes, patient monitors, needles, catheters, dilators, and soft-touch buttons. Wearable devices combining rigid housings with comfortable skin contact surfaces.

• Auto Trims

Car trims or moldings are components found in various parts of an automobile, including the door edges, side body, fenders, bumpers, wheels, and interior areas. While car trims often serve a decorative purpose, they also offer practical benefits, such as reducing the vehicle's weight. Over-molding, as discussed earlier, provides several functional advantages and is a versatile plastic production technology with numerous creative applications. It allows for the creation of custom or pre-set automotive trims in a range of colors, tailored to customer preferences.

To be combined with additional materials like steel, chromium, or metal plating, over-molded trims can undergo a different process called insert molding.

• Consumer Electronics

Smartphone and tablet cases

Gaming controller grips

Waterproof electronic enclosures

Advantages of Over-molding

The over-molding technique offers several advantages that can be observed across various applications:

• Boost IP Rating

The over-molding technique creates a protective bond around PCB’s, wires, cables, and connectors, safeguarding electrical components from dirt, dust, and debris. An over-molded electrical assembly can achieve IP67, IP68, and IP69K ratings for protection.

• Improve design efficiency

It is feasible for complex assembly design and manufacturing of multi-material parts with over-molding. For example, the manufacture of automobile headlights uses insert or two-shot molds.

• Greater Efficiency

Over-molding guarantees a proper alignment and rigid assembly of mating parts, so it can improve the product quality and performance. This approach can result in products that last longer compared to those made from a single material and assembly.

Moreover, over-molded products are better at absorbing shock and vibration. Additionally, over-molding can enhance a product's chemical resistance.

• Cost-Effective

Over-molding allows manufacturers to create one piece product without more assembly, so less components used and secondary operations. Additionally, the easier process makes it particularly valuable in industries that require rapid production, reduce labour costs, so high-quality outcomes keep manufacturing costs low.

• Improve product ergonomics and user experience

Over-molding is to provide rubber grips for tools, like toothbrushes and other hand-held products. The rubber grip helps to improve the ergonomics of the product. Two-shot injection molding and co-injection molding are used to manufacture parts with multiple colors. And it can improve the aesthetics of the product.

• Customization

One of the less obvious benefits of over-molding cable assemblies is the degree of customization it allows. While it is possible to over-mold existing assemblies, manufacturers can also create a custom product tailored precisely to the specific needs of a given application.

Challenges of Over-molding

While the over-molding process offers numerous benefits, it also presents several challenges and limitations that manufacturers must consider.

• Potential Challenges with Material Compatibility

One of the primary challenges in the over-molding process is ensuring material compatibility between the substrate and the over-mold materials. Not all materials bond well together, which can lead to issues such as delamination or weak interfaces. Manufacturers must conduct thorough compatibility testing to ensure that the selected materials will adhere properly during the over-moulding process. This includes evaluating chemical compatibility, mechanical bonding and thermal properties to avoid potential failures.

• Limitations in Design Complexity Due to Mold Constraints

Over-molding imposes certain design constraints that can limit creativity and complexity. The need for specialized molds can restrict the geometric freedom of parts. Complex shapes or intricate features may not be feasible due to the limitations of mold design and manufacturing processes . Additionally, consistent wall thickness is often required to ensure proper flow of materials during injection, which can further constrain design options. These limitations may necessitate compromises in product design, potentially impacting functionality and aesthetics.

• Risk of Warpage or Defects if Not Properly Managed

The risk of warpage is a significant concern in over-molding, particularly due to differential shrinkage between the two materials during cooling. If not managed properly, this can lead to defects such as uneven surfaces or structural weaknesses in the final product . Factors contributing to warpage include variations in wall thickness, improper cooling rates, and inadequate mold design. Manufacturers must implement best practices for mold design and processing parameters to minimize these risks, such as optimizing cooling systems and ensuring uniform wall thickness throughout the part.

Quality Control in Over-molding

At PTSMAKE, we implement rigorous quality control measures:

1. Pre-production Testing

◦ Material compatibility verification

◦ Mold flow analysis

◦ Prototype evaluation

2. In-process Controls

◦ Temperature monitoring

◦ Pressure verification

◦ Cycle time optimization

3. Post-production Inspection

◦ Visual inspection

◦ Adhesion testing

◦ Dimensional verification

Conclusion

In summary, the over-molding process is a sophisticated technique that combines two or more materials to create a single, integrated component. This method enhances product functionality, aesthetics, and durability across various industries, including automotive, electronics, medical devices, and consumer goods. XHT is a professional manufacturer supply overmolding injection molding services. Welcome to contact if any over-moulding project requirements.